Neue Weine BEI WINZER24.de

Beliebte Weinarten

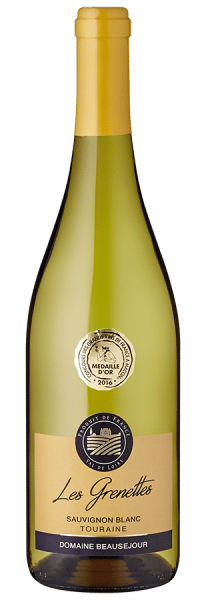

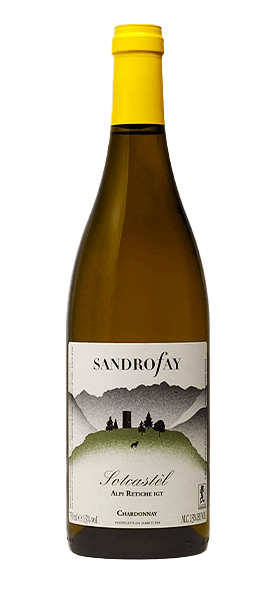

UNSERE Weinart EMPFEHLUNGEN

Beliebte Weinländer

UNSERE EMPFEHLUNGEN nach WEINLAND

Beliebte Rebsorten

UNSERE EMPFEHLUNGEN nach Rebsorte

Aus unserem Magazin

Weinliebhaber aufgepasst: Eine Reise durch die schönsten Anbaugebiete

Ein Spaziergang durch die Reben und danach ein Gläschen des besten Weins der Region. Für Weinliebhaber gibt es oft nichts Schöneres als einen Aufenthalt in den wunderschönen Weinanbaugebieten. Quer über

Bad Cannstatt Weine – ein Muss für Weinkenner

Einige der besten deutschen Weine, darunter der wahrscheinlich beste Lemberger, kommen aus Weingütern des ältesten Stuttgarter Stadtbezirks Bad Cannstatt. Dafür ist auch die Lage verantwortlich: Die Siedlung beiderseits des Neckars

Drei Tipps um einen guten Wein zu erkennen

Ein beliebtes alkoholisches Getränk, das um die Welt geht: der Wein. Seit vielen tausenden von Jahren trinken die Menschen Wein und schätzen die ausgeprägte Vielfalt von diesem edlen Tropfen. Dabei

Wie viel sollte ein guter Wein kosten?

Weine sollen gut schmecken – aber wie viel sollen sie kosten? Da scheiden sich die Geister. Manch ein Weinliebhaber würde niemals einen Tropfen für weniger als 20 Euro anrühren. Manch

Die besten Weinrestaurants Deutschlands

Die besten Weinrestaurants in Deutschland listet alljährlich der Weinbar- und Cocktailbarguide. Im Jahr 2021 führte er für das gesamte D.A.CH.-Gebiet insgesamt 350 Weinbars und 700 Cocktailbars, deren Besuch sich unbedingt

Weingut – ein Paradies für Weinliebhaber

Ein Weingut ist ein Landwirtschaftsbetrieb, der edle Weinreben anbaut und die geernteten Trauben zu Wein, Sekt und Perlwein verarbeitet. In der Regel erfolgt auch die Vermarktung vom Weingut aus. Weingüter

Weinfest

Ein Jahr ohne Weinfeste ist ein verlorenes Jahr. Lasst uns heute über Weinfeste reden. Wer hatte eigentlich die geniale Idee Weinfeste ins Leben zu rufen? Unter uns Weinfreunden ist ja

Wie du den perfekten Wein zum Abendessen auswählst

Wenn es um Wein geht, sind die Möglichkeiten endlos. Es gibt so viele verschiedene Weinsorten, dass es schwierig sein kann, sich für einen Wein zum Abendessen zu entscheiden. Mit ein

Auf winzer24.de findest du mit Sicherheit den richtigen Wein für jeden Anlass!

Du suchst nach einem neuen Wein zum Probieren oder ein Geschenk? In unserem Weinshop findest du eine große Auswahl an verschiednen Weinen und Champagner aus der ganzen Welt. Wir haben für jeden etwas dabei, egal ob du nach einem Rot-, Weiß- oder Schaumwein suchst. Unsere Partner haben jeden Wein auf unserer Website handverlesen, damit du sicher sein kannst, dass du ein Qualitätsprodukt bekommst.